Edge Crush Test (ECT)

An edge crush test method is one method used to test the strength of corrugated fiberboard. Using this method, the test operator will cut a sample of material and subject it to a top load in the edge-down orientation. The ECT edge crush test provides valuable data to determine if the corrugated fiberboard material that you specified is what you received.

Edge Crush Test

Definition: The edge crush test (ECT) is used to assess corrugated fiberboard’s capacity to sustain cross-sectional pressure.

Because of its built-in reinforcements, corrugated fiberboard is a durable packing material used across industries worldwide. However, packages are constantly exposed to pressure and stacking in distribution, transit, and storage environments. An edge crush test plus McKee’s formula can assess the theoretical strength of a corrugated fiberboard box under these circumstances, and as a result, its ability to protect contents when exposed to various forces that are common in warehouse and distribution environments.

What is an Edge Crush Test (ECT)?

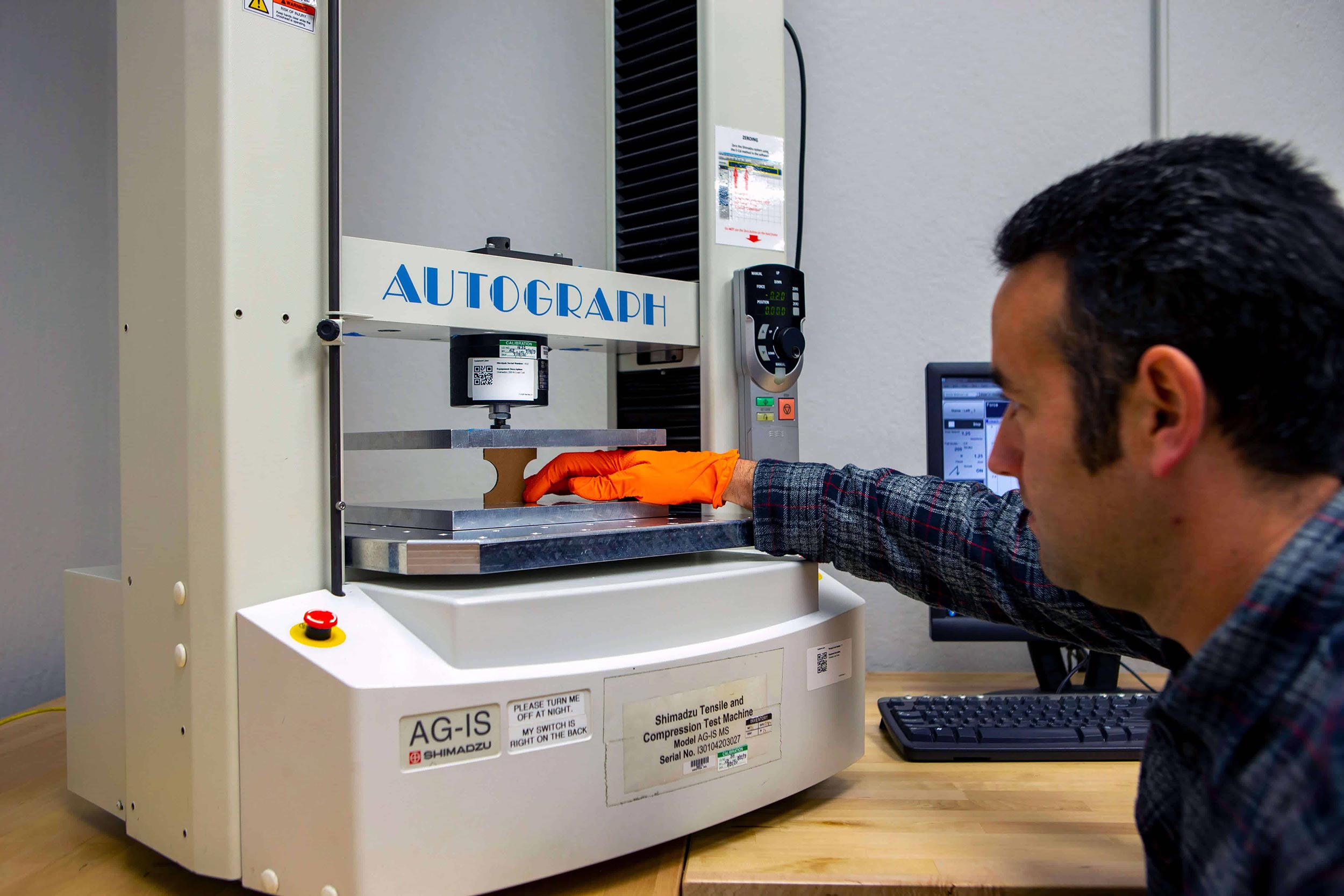

An edge crush test method is one method used to test the strength of corrugated fiberboard. Using this method, the test operator will cut a sample of material and subject it to a top load in the edge-down orientation. The ECT edge crush test provides valuable data to determine if the corrugated fiberboard material that you specified is what you received.

Typical Protocols for an Edge Crush Test

Westpak testing facilities adhere to the following protocols when performing edge crush tests:

- TAPPI T 811

- TAPPI T 838

What are the advantages of an edge crush test?

By testing the strength of corrugated fiberboard packaging, manufacturers can establish a high degree of confidence in their packaging systems that they are receiving a consistent quality of packaging materials from their suppliers. The ECT edge crush test allows you to get consistent materials from multiple suppliers in a global distribution environment.

When you input the ECT value into McKee’s formula, you can determine the theoretical maximum value your package can support. If you would like to use McKee’s formula, you can find it using Westpak’s Box Compression Test Calculator.

What is the difference between an edge crush test and Mullen burst test?

Corrugated fiberboard is typically assessed using edge crush testing and/or Mullen burst testing. While both measure the strength of the material under external pressure, they’re unique in their testing and reporting. Let’s take a look at the differences between the two:

- Edge crush test: ECT measures the edgewise compressive strength of corrugated fiberboard. This maximum load to cause failure is determined by compressing an hourglass shaped piece of corrugated fiberboard on its edge between two rigid platens perpendicular to the flutes’ direction until a peak load is reached. This is expressed in pounds per lineal inch (lb/in).

- Mullen Burst test: During a burst test, a Mullen burst tester measures the force necessary to puncture the face of the corrugated board sample. This force is a function of the material’s ability to withstand external or internal stresses. This test allows you to get consistent materials from multiple suppliers. . The Mullen burst test’s results are measured in pounds per square inch (psi).

Both Mullen burst testing and edge crush testing provide a way to ensure that you are receiving the materials you have specified, and compare suppliers from around the world. However, ECT has become the more common of the two in the test industry, as you can use McKee’s formula to get a baseline for the theoretical compression strength of your package.

Which standards include an edge crush test (ECT)?

Typical standards specifying edge crush testing include:

- TAPPI T811

- TAPPI T823

- TAPPI T838

- TAPPI T839

- DIN EN ISO 3037

- APPITA/AS 1301.444s

- FEFCO 8

- ISO 13821

- SCAN P33

Accreditations:

Testing at WESTPAK has been accredited by A2LA to comply with ISO 17025.

WESTPAK testing labs are ISTA certified to perform a variety of tests.