We’ve all done it. That slow motion moment when your fancy smart phone falls from your hand and towards the concrete. At stake is the modern badge of a life well lived, a cracked smart phone screen. We do our best to protect these investments with cases and handy-dandy belt clips (people still have belt clips, right?), but in the end rely on a well designed and tested device to handle such inevitable events.

If you are responsible for the design of devices or their protective packaging, you have the opportunity and obligation to make a difference for those everyday users who will drop your products. Through proper shock and impact testing you can test to know and improve their limits to shock and impact events in the end use environment.

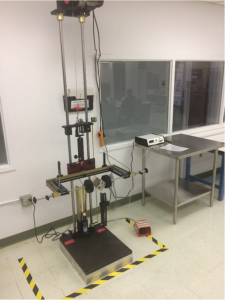

In addition to traditional shock testing, Westpak is pleased to announce the purchase and installation of a Guided Orientation Product Freefall Drop Tester in our San Jose Laboratory. The ESSM-2 Drop Test System was purchased from GHI Systems and is a great addition to our suite of product testing capabilities.

The system can drop small products from the size of a tape measure to a laptop computer in a controlled manner. Unlike standard free-fall drop testing, this system allows the product to be drop-tested on specified corners, edges, and faces.

The system can drop small products from the size of a tape measure to a laptop computer in a controlled manner. Unlike standard free-fall drop testing, this system allows the product to be drop-tested on specified corners, edges, and faces.

With the ESSM-2 Drop Test System, drop heights up to 4.5 feet (1.1m) can be achieved. Some common impact surfaces include steel plate, laminate floor, tile, wood, and cement block. The system is complaint to IEC 60068-2-31.

As you can see in the picture on the left, a classic handheld game console is ready for a corner drop onto a steel plate. The carriage drops and the guide arms will retract just prior to impact.

Please contact us if you have a project you’d like to have run on this system!

And hey, if you’ve got that cracked screen, here’s a handy source for you to make reparations. Good luck!