ASTM F1929

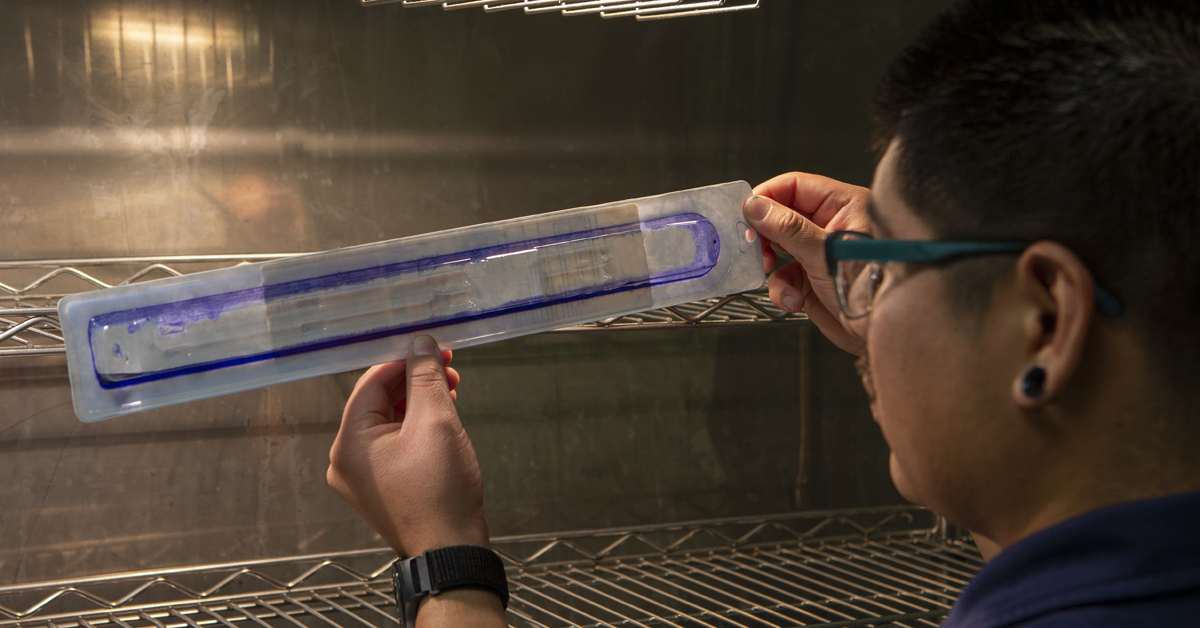

ASTM F1929 is a standardized integrity test used to evaluate and identify potential leaks in porous medical packaging. The standard includes a series of test methods that use dye to find leaks generated by channels or other imperfections following the sealing process. The standard can be used for both pouches and trays with a transparent layer and sealed with a porous substrate.

ASTM F1929

ASTM F1929 is a standardized integrity test used to evaluate and identify potential leaks in porous medical packaging. The standard includes a series of test methods that use dye to find leaks generated by channels or other imperfections following the sealing process. The standard can be used for both pouches and trays with a transparent layer and sealed with a porous substrate.

Purpose of ASTM F1929

ASTM F1929 is a standard test designed to identify and locate leaks in porous medical packaging. Any leak will compromise the Sterile Barrier System (SBS) and may allow the ingress of microorganisms causing contamination of the medical device. This type of testing is especially important to illustrate the integrity of the SBS has been maintained following a distribution test.

ASTM F1929 uses a specific dye penetrant to conduct the dye leak testing which can identify leaks in a SBS using one of the following methods:

- Injection

- Edge Dip Method

- Eye Dropper Method

Each of these test methods functions differently and is better suited for some products than others. Below, we’ll take a look at the differences between these methods in greater detail.

There are many types of dye leak testing, but the ASTM F1929 standard describes materials and a technique that will identify and locate a leak equal to or greater than a channel formed by a 50μm (0.002 in.) wire.

What are the various test methods for a dye penetration test?

ASTM F1929 testing is performed by applying dye to a SBS using one of the following methods:

- Test Method A (Injection): Inject dye solution into the sealed package and look for leaks originating from the inside edge of the package seal through the outside edge. In a worst case dye would drip out of the package.

- Test Method B (Edge Dip Method): Dip the outer edge of the package seal equally in the dye solution and look for leaks that originate from the outside edge of the package seal and travel through to the interior edge. This uses capillary action to wick the dye up into the defect.

- Test Method C (Eye Dropper Method): The eye dropper method can only be used for pouches that have an unsealed area that extends beyond the outer edge of the seal. To administer dye, the test personnel will start by separating the transparent material from the porous material. Once the substrates are separated, they can use a pipette or eye dropper to apply dye between the two substrates allowing the dye to run along the sealed edge. The package is then examined for leaks that originate from the outside edge of the SBS and travel through the interior edge.

What are the requirements for ASTM F1929 testing?

- ASTM F1929 testing is only compatible with porous materials. Porous packaging is prone to wicking, therefore, the entire inspection of the seals should be conducted in less than 20 seconds.

- Packaging must not have any condensation or other source of liquid water. Pre-existing water found in the seal may compromise the test, making leaks undetectable with a dye penetrant.

- The test method ASTM F1929, requires that the color of the dye penetrant has good contrast to the opaque packaging material.Is ASTM F1929 testing intended for specific types of packages?

Is ASTM F1929 testing intended for specific types of packages?

Yes, ASTM F1929 is designed to detect and locate leaks found in a medical device SBS formed with transparent substrate and a porous substrate.

Should I test my medical device packaging with ASTM F1929 or ASTM F2096?

ASTM F1929 and ASTM F2096 are both considered package integrity tests used in the medical device industry. These tests are designed to detect potential breaches or manufacturing defects in a SBS. Leaks that are detected in the SBS have the potential to compromise patient safety. These tests are used following other tests or test sequence to determine if the integrity of the packaging was maintained.

While both test methods assess SBS integrity, they utilize a different means to achieve similar results.

- ASTM F1929 uses a dye leak penetrant to identify a breach in the SBS when the package is sealed or the seal is compromised. In other words, it evaluates the sealing process or if seal damage, such as seal creep, has occurred following a dynamic event.

- ASTM F2096 uses air to create a positive pressure inside the SBS and bubbles form on the outside of the porous substrate. The integrity of the entire SBS is tested, not just the seals. Any defects down to 250μm (0.01 in.) can be detected accurately using this method.

Both ASTM F1929 and ASTM F2096 provide valuable insights into the integrity of a medical device package and are a good indication that the device is sterile. If you’re unsure which test method would best suit your needs, contact WESTPAK and our team can help.

Accreditations:

Testing at WESTPAK has been accredited by A2LA to comply with ISO 17025.

WESTPAK testing labs are ISTA certified to perform a variety of tests.