ASTM F88: Seal Strength / Seal Peel Test

Seal strength testing, also known as peel testing, is used to determine how much force is required to separate two bonded surfaces.

Seal Strength Test (Seal Peel Test)

Seal strength testing is commonly used in the medical device industry to evaluate the strengths of seals on pouches and packages. Conducting a seal strength test allows medical device manufacturers to determine how secure their primary packaging is. A weak seal can compromise a product’s Sterile Barrier System (SBS) and thereby negatively impact the patient safety and efficacy of the product itself.

What is the purpose of a seal strength test?

A seal strength test aims to evaluate the effectiveness of product packaging objectively and measurably. Product packaging systems must ensure a minimum seal strength to prevent contamination or damage due to environmental factors. If the seal on a sterilized pouch or package fails before the end user opens it, sterility could be lost, rendering the product unsafe. Clients will likely be unable or unwilling to accept product delivery with a compromised Sterile Barrier System.

Sterility is particularly important when it comes to the medical device industry. Medical device manufacturers must take proper measures to maintain product sterility until usage. A Sterile Barrier System’s (SBS) microbial barrier must protect against bacteria and other microorganisms.

A seal strength test is beneficial for more than just measuring the seal strength of an individual product. The test also evaluates the manufacturer’s ability to produce effective package seals consistently. Standardized procedures like ASTM F88 can ensure that manufacturers comply with industry standards and meet the Administration (FDA) mandates.

Frequently Asked Questions

Get answers to our most frequently asked questions.

What does ASTM F88 measure?

An ASTM F88 Seal Strength is used to assess the peel strength of flexible barrier materials utilized in medical packaging systems. The ASTM F88 standard provides two measurements:

- Average Seal Strength: The average force required to separate a flexible material from a rigid one, or two flexible materials from each other.

- Maximum Seal Strength: The maximum amount of force required to separate a flexible material from a rigid one, or two flexible materials from each other.

What is the test procedure for peel testing?

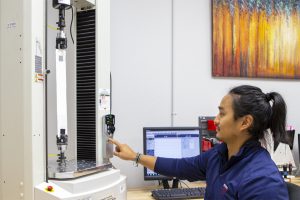

The seal strength test employs a universal testing machine with its jaw separation rate set between 200 to 300 mm/min (8 to 12 in/min). The test procedure is as follows:

- Use a sample cutter to cut a one-inch wide strip in the seal on each of the four sides of the pouch or package.

- Line the stiff side of the sample up so that it can be easily clamped in the top grip.

- Proceed with the peel testing by separating the bonded surfaces at a rate that ranges from 200 to 300 mm/min ( 8 to 12 in/min).

- Record the maximum force used to separate the two bonded surfaces and make note of how these surfaces separated.

After the testing completes, calculate the average seal strength and maximum seal strength.

What are the three techniques that can be used for a seal peel test?

There are three distinct seal integrity test methods that can be used. The different techniques exist in order to hold samples at a variety of angles and manage bending forces. As dictated by ASTM F88, the standard seal strength test techniques are as follows:

- Technique A: The tails of the sample are clamped into opposing grips while the seal itself remains unsupported throughout the test.

- Technique B: The tails of the sample are supported in opposing grips, while the seal itself is hand-supported at a 90-degree angle that brings it to a perpendicular position in relation to the tails.

- Technique C: The least flexible of the sample’s tails are held flat using an alignment plate secured by a grip. At the same time, the more flexible tail is brought 180 degrees over the seal and secured in an opposing grip.

Accreditations:

Testing at Westpak has been accredited by A2LA to comply with ISO 17025.

Westpak testing labs are ISTA certified to perform a variety of tests.