Dye Penetration Test

Dye penetration testing is a cost-effective and common method used to identify potential channel leaks or other defects in the seals of a package.

What is the purpose of a dye penetration or leak test?

Dye penetration testing is used to visually assess potential defects within a sterile barrier system’s seal, most often for medical devices. This test standard is a straightforward methodology that can provide valuable insights into defects in the material or packaging process, particularly validating the seal integrity for medical devices. Most commonly evaluated packaging materials examined with dye leak testing include porous materials such as Tyvek(R) or paper along with non-porous materials such as poly or foil.

The test procedure injects a package with sufficient dye solution to generate a depth of 5 mm (0.25 in) along the longest edge of the inner seal. The trained test operator looks for defects and leaks along the seals of the package that may impact the general safety and efficacy of the sterile barrier system (SBS).

Why is a dye leak test important?

Having leaks is detrimental to a product’s lifecycle. Hazardous biological or particle contaminants can enter a device through seal defects, which are usually found along or near a package’s seal. Through dye penetration testing, test operators can identify packaging flaws that compromise product safety and reduce shelf-life. Armed with test data, manufacturers can develop solutions that fortify seals before releasing their products to market and the distribution environment.

Beyond safety and efficacy assurance, dye leak testing can also help manufacturers avoid costly packaging missteps during the packing and distribution process.

How is dye penetration testing performed?

Our accredited labs are fully equipped for dye penetration testing. Typical test standards used for dye testing are ASTM F1929 and ASTM F3039.

As per the protocols, our process for dye penetration testing adheres to the following steps:

- The dye penetrant is applied to the sample by using a syringe, eye dropper, or dipping the external seal, depending on the test method.

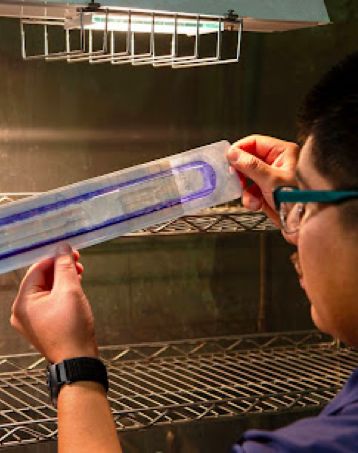

- The penetrant is distributed evenly along the seal while the operator inspects for leaks and defects. The maximum inspection time per seal should not exceed 5 seconds. This is repeated for all seals to be tested.

- Excess penetrant is removed and the component is dried.

- The test operator inspects the sample under ultraviolet or white light and documents notes as required.

Upon test completion, Westpak will provide a detailed report to the customer with the findings from the testing. With this context, manufacturers and packaging specialists can make more informed decisions regarding their product and its packaging.

Frequently Asked Questions

Get answers to our most frequently asked questions.

What are some of the advantages of performing a dye penetration or leak test on a package?

Dye penetration or leak testing provides valuable insights regarding the safety and efficacy of the seals of a sterile barrier system (SBS). However, like all test methods, there are both advantages and limitations. Understanding the advantages and drawbacks can help you determine what test methodology is best suited to your product.

Dye leak or penetration testing advantages:

- High sensitivity to small surface flaws presented on the seals

- Complex seal shapes can be easily inspected

- Efficient inspection of large samples and large volumes of materials

- Applicable to many types of materials

- Provides a visual representation of the defect, which can be readily identified directly on the sample

- Test results can reveal the relative size, shape, and depth of inconsistencies

Dye leak or penetration testing limitations:

- Mainly identifies flaws present in the seals of a package

- Test operator must be properly trained and experienced in order to not conclude false positive failures

- Dye penetration fluid is destructive with respect to coloring any internal package contents. As a result, the product must either be extracted beforehand or a dunnage product must be used.

Not sure if your package should undergo dye leak testing? Our experienced team can help you consider the potential advantages and limitations of its methodology to assess whether it’s the right fit for your product.

What test equipment is needed to perform a dye penetration test?

Testing equipment can vary depending on the test sample and the standard followed. Typical test equipment required for a dye penetrant test include:

- Dye penetrant solution including a surfactant and indicator dye

- Knife or other small apparatus to penetrate part of the packaging system

- A dropper or other dispenser to apply dye

- Ample lightning for inspections

What are the dye penetration test standards?

There are mainly two dye penetration test standards set forth by ASTM, which are the ASTM F1929 and ASTM F3039 test standards.

Accreditations:

Testing at Westpak has been accredited by A2LA to comply with ISO 17025.

Westpak testing labs are ISTA certified to perform a variety of tests.